Veolia to pilot new carbon capture technology from EfW

The pilot project will test an innovative technology designed to reduce carbon emissions produced by energy from waste (EfW) facilities. If successful, the new process could save 100,000 tonnes of carbon per year across Veolia’s EfW sites in the UK, the company has said.

The carbon capture utilisation and storage (CCUS) system, engineered by Veolia’s in-house design teams, uses the Advanced Amine Process to capture CO2 from the incineration of municipal waste. Amines are well-suited to carbon capture as they react reversibly with CO2.

Veolia claims that the CO2 derived from biogenic waste (which comprises about 60 per cent of all CO2 produced during the incineration process) can be combined with green hydrogen to make fuels such as eMethanol and Sustainable Aviation Fuel, which could help to lower transport emissions. The CO2 derived from non-biogenic waste would be stored.

Veolia claims that the CO2 derived from biogenic waste (which comprises about 60 per cent of all CO2 produced during the incineration process) can be combined with green hydrogen to make fuels such as eMethanol and Sustainable Aviation Fuel, which could help to lower transport emissions. The CO2 derived from non-biogenic waste would be stored.

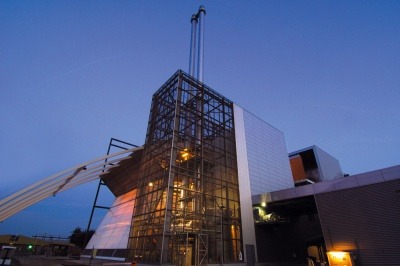

Veolia, which operates ten EfWs in the UK and processes around 2.3 million tonnes of non-recyclable waste per year, has launched a feasibility study to determine which of its sites will host the CCUS pilot project.

Commenting on the new technology, Donald Macphail, Chief Operating Officer - Treatment, at Veolia said: "This latest innovation marks a major step forward in our ability to utilise non-recyclable waste and captured CO2 to create the next generation of fuels.

“This development, combined with greater recycling and the removal of plastics from waste streams, will further reduce carbon emissions from [Energy Recovery Facilities]. It will also make a major contribution to meeting Net Zero targets that protect the environment for the future, and supports our commitment to achieve ecological transformation."

The CCUS process has four key stages. First, the Flue gas is cooled and its trace pollutants removed. Second, an Amine solvent captures the CO2 and clean flue gases are returned to the flue. Third, the solvent is heated with steam from the [Energy Recovery Facilities] to produce a CO2-rich stream. Fourth, the CO2 is dehydrated and compressed to produce a nearly 100 per cent pure CO2 stream, while the solvent is circled back to the absorption process.

This investment reflects an ongoing trend as operators explore ways to reduce carbon dioxide emissions with the anticipated introduction of EfW facilities to the UK Emissions Trading Scheme in 2028.