Greyparrot AI: powering the MRF of the future

SPONSORED CONTENT

To run a profitable plant, operators need accurate composition data on waste flows in real-time. Computer vision is an area in artificial intelligence (AI) that uses camera systems to capture and analyse images and videos, identifying and categorising objects.

To run a profitable plant, operators need accurate composition data on waste flows in real-time. Computer vision is an area in artificial intelligence (AI) that uses camera systems to capture and analyse images and videos, identifying and categorising objects.

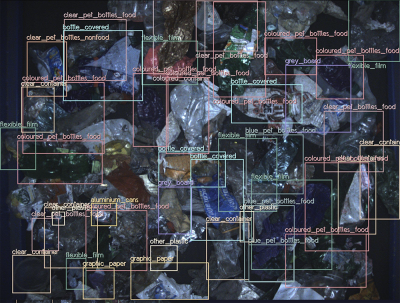

When applied to MRFs (Material Recovery Facilities), recent advancements in this technology allow machines to ‘see’ and classify waste at human-level recognition or better. Greyparrot has applied this technology to create an AI Waste Recognition System that automates the monitoring, auditing, and sorting of waste at scale. It involves a camera system that is retrofitted on top of conveyor belts and a live dashboard that displays waste composition data insights in real-time. Greyparrot provides a Vision Integration API, which allows integration of this data feed into software systems, sorting machines, and robots to enhance their sorting capabilities.

Operators in the UK and elsewhere have installed the Greyparrot system for different goals. Biffa, a leader in the UK’s recycling industry has the Greyparrot system installed in its Plastic Recycling Facilities. Site manager Ian McSpirit explains, “We’re using the systems to provide real-time analysis on the purity of our PET output material.” With this, Biffa can prove the quality of its secondary materials to buyers and determine a price based on purity. Video evidence can also show exactly what is in each bale.

Greyparrot’s system is built with affordable hardware which relies on intelligent self-learning software and can easily be retrofitted across several points in a facility. Working with industry leaders such as Veolia and Suez, Greyparrot is already adopted by 60 per cent of the European market to reduce cost and increase profitability.

To learn more, visit Greyparrot's website.